Rubber Compounding

Controlled formulations and mixing cycles designed for stable grip, wear and rolling resistance characteristics across batches.

From compounding to final inspection, every stage is designed for consistency, repeatability and OEM-aligned quality.

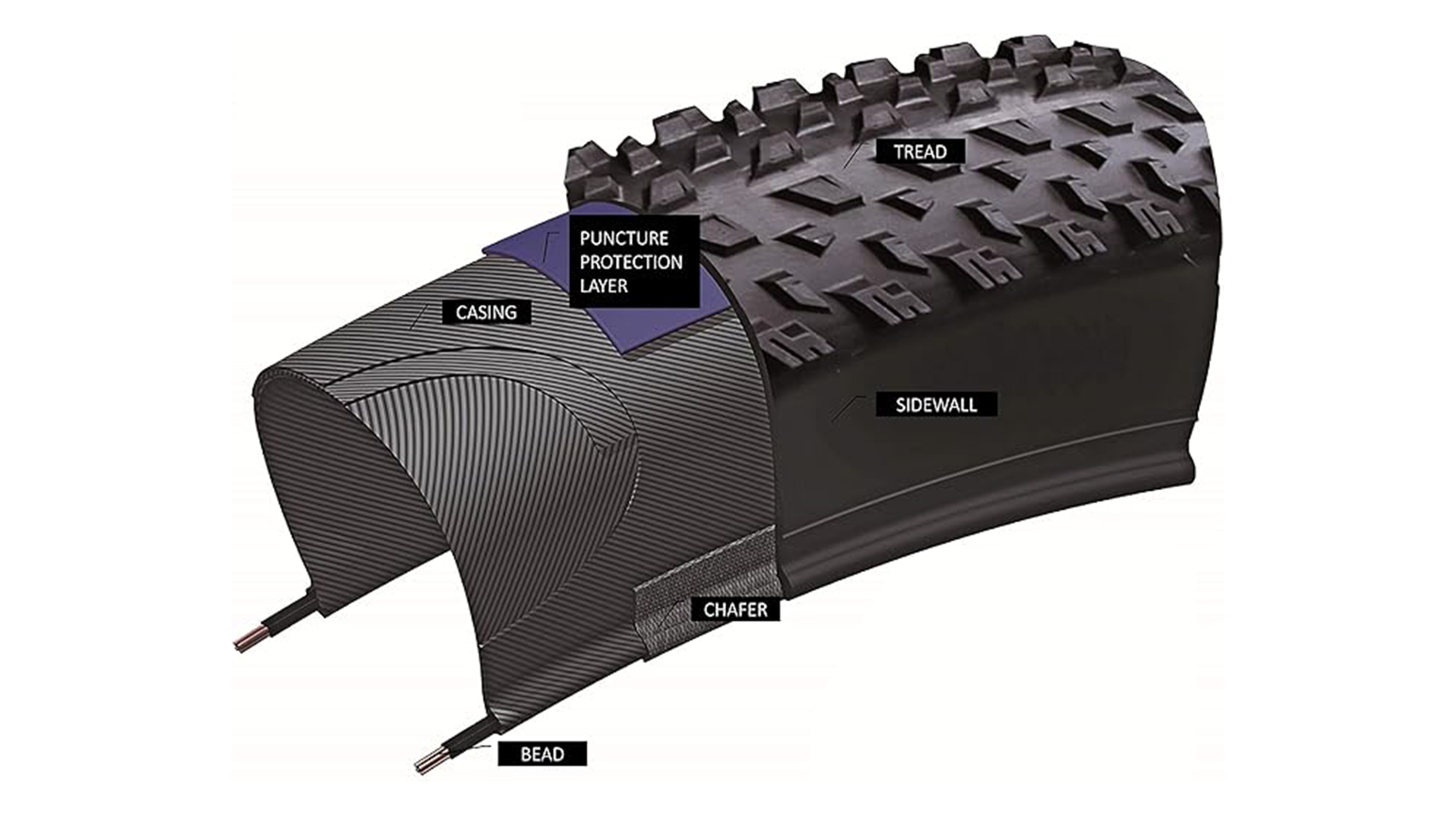

The Maxtron infrastructure is set up to support bicycle, two wheeler and agriculture tyres with a clear focus on process discipline. From raw material handling and compounding to curing and final inspection, each step is monitored and documented.

This manufacturing backbone allows Maxtron to serve replacement markets today while building long-term readiness for OEM and export requirements.

Controlled formulations and mixing cycles designed for stable grip, wear and rolling resistance characteristics across batches.

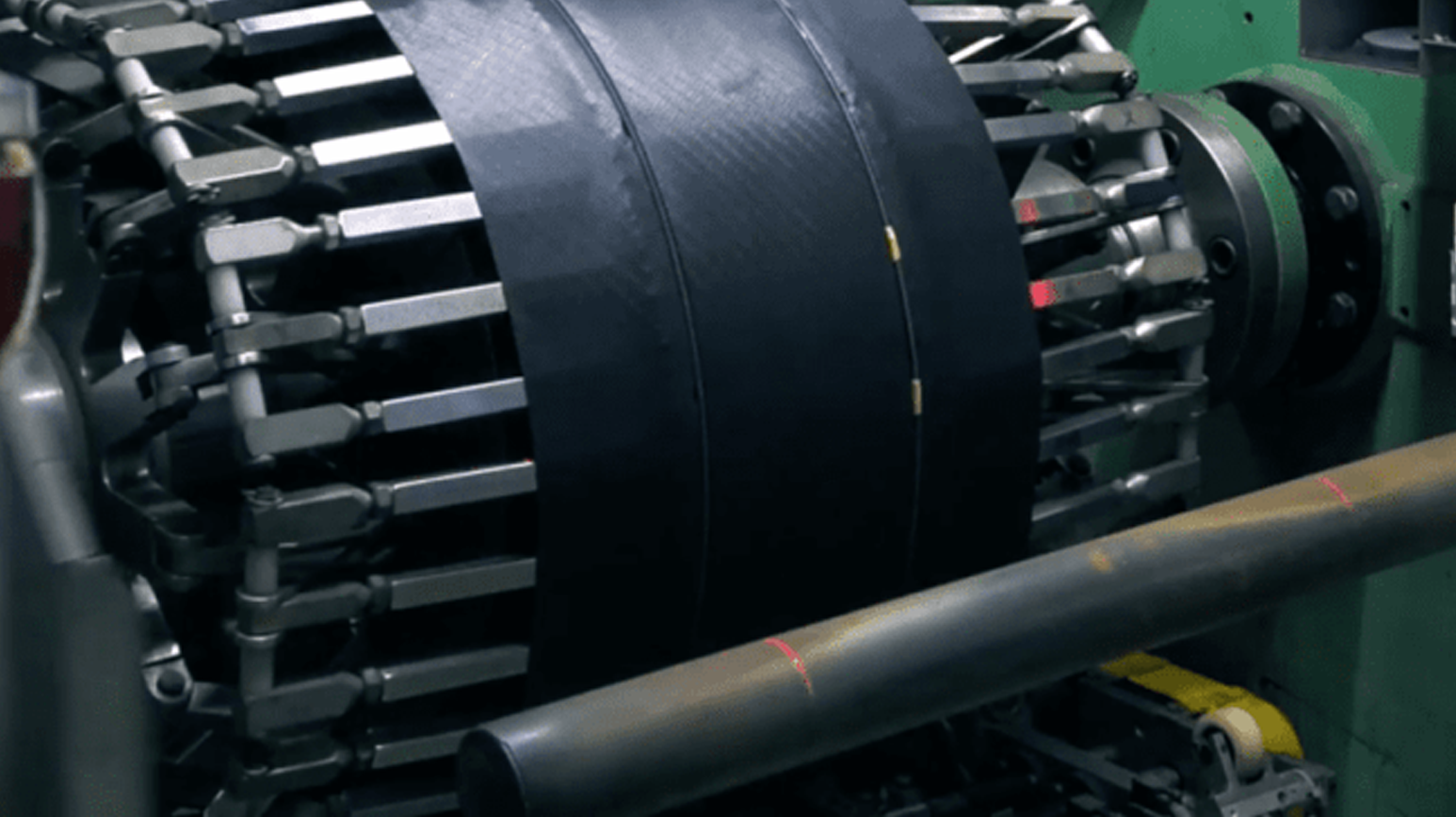

Tyre building stations aligned to segment-specific requirements – from lighter bicycle casings to load-focused agricultural constructions.

Precision moulds and controlled curing parameters ensure accurate tread geometry and uniformity.

Maxtron uses lab testing and field feedback together to tune patterns and compounds. Testing covers key behaviours like load, rolling resistance, endurance and compound wear.

Share your requirement and our team can support with infrastructure details, certifications and audit readiness.